How to choose the right saw blade

- Share

- Issue Time

- May 7,2022

Summary

Making smooth, safe cuts with a desk noticed, radial arm saw, chop saw, or sliding compound miter noticed relies upon on having the right blade for the tool and the sort of reduce you want to make. There's no shortage of great options, and the sheer range of blades available can confuse even pro woodworkers. It is why we prepare this article. It is part word list and part manual and incorporates essential basic data that will help you pick the right noticed blade preference on your venture.

Desk noticed blade

Making smooth, safe cuts with a desk noticed, radial arm saw, chop saw, or sliding compound miter noticed relies upon on having the right blade for the tool and the sort of reduce you want to make. There's no shortage of great options, and the sheer range of blades available can confuse even pro woodworkers. It is why we prepare this article. It is part word list and part manual and incorporates essential basic data that will help you pick the right noticed blade preference on your venture.

A way to select the proper saw blade?

An excellent way to slim down your picks and focus your seek is to reply a few key questions:

What sort of noticed will the blade be used for? A few blades are designed to paintings with a specific saw, so that you'll want to make certain you get the proper blade for the tool. The use of the incorrect form of noticed blade can produce unwanted results and, in some instances, may be dangerous.

What materials will the blade be used for reducing? If you need to cut a extensive range of materials, on the way to affect your desire. Specialization may have an impact on your preference if you cut a number of a unmarried sort of material (eg melamine).

What type of cuts will the blade be used for? Will or not it's used completely for cross slicing (move slicing wood grain)? Is it best for ripping (cutting with grain)? Does it need to paintings well in all styles of cuts?

Do you want to construct a variety of specialised blades, or do you need a blade that can make a variety of cuts? Might you want to alternate the blade each time you turn from one reduce to every other?

How powerful is the noticed that makes use of the blade, and what size blade does the producer endorse? Is it a three hp cabinet desk saw or a portable jobsite saw? 10" noticed or 12"?

Answering those questions will go a long manner in clarifying your fine options. Understanding a little approximately the anatomy of a noticed blade can assist slim your seek further. Saw Blade Highlights Many saw blades are designed to provide the nice consequences for a specific slicing operation. You could get unique blades for slicing wood, move-slicing wooden, cutting plywood and panels, cutting laminates and plastics, reducing melamine and slicing non-ferrous metals.

Noticed blade factors

Many saw blades are designed to offer the great results in a specific reducing operation. You can get unique blades for slicing wood, cross-reducing wood, slicing plywood and panels, reducing laminates and plastics, reducing melamine and reducing non-ferrous metals. There are also typical blades and combination blades, designed for two or greater kinds of cuts. (The aggregate blade is designed for go reducing and tearing.

Popular blade designed to make all kinds of cuts such as plywood, laminated wood and melamine. ) The most reliable overall performance of the blade relies upon in component on the wide variety of enamel, the scale of the esophagus, the tooth form and the hook attitude (tooth attitude).

Range of tooth

In popular, a blade with a higher quantity of teeth will produce a smoother reduce, while a blade with a decrease range of enamel will cast off fabric faster. As an instance, a ten-inch blade designed to split timber generally has most effective 24 enamel and is designed to speedy eliminate fabric along the length of the grain. Splitting blades are not designed to produce a reflect-easy reduce, however an amazing ripping blade will reduce through hardwood resultseasily and depart a smooth reduce with minimum scratching.

Crosscut blades, alternatively, are designed to supply smooth cuts inside the wood grain without splitting or tearing. Blades of this type usually have 60 to 80 tooth, with a higher wide variety of tooth meaning less cloth must be removed according to tooth. In comparison to ripping blades, move-cutting blades make more person cuts as they skip through the billet and consequently require slower feed quotes. The end result is a cleaner side reduce and a smoother reduce floor. With pinnacle-high-quality cross-reducing blades, the cut floor will appearance clean.

Esophagus

The esophagus is the space in the front of every teeth that is used to remove chips. In ripping operations, the feed charge is quicker and the chip size is greater, so the esophagus needs to be deep enough to deal with massive volumes of fabric. In move-reduce inserts, the chips are smaller and there are fewer enamel in line with enamel, so the teeth area is a good deal smaller. The gullets on a few crosscut blades are also purposely designed to be small to suppress excessively fast feed costs, which can be a problem, specially on radial arm saws and sliding miter saws. The gullet of the mixture blade is designed to handle tearing and move slicing. Massive alveoli between businesses of tooth help to take away the majority of cloth created during tearing. Smaller cogging among grouped tooth suppresses excessively rapid feed rates when traversing.

Move-blade and tear-blade pictures

Blade tooth configuration

The form of the blade teeth and how the enamel are grouped also influences how the blade cuts. The configuration of teeth on a noticed blade has plenty to do with whether the blade is exceptional suited for tearing, pass-reducing, or laminating.

Flat pinnacle (feet)

Blades with flat pinnacle tooth for slicing hardwoods and softwoods. For the reason that wood is less possibly to chip and splinter whilst cut with the grain, the ripping blade is designed to get rid of fabric speedy and successfully. Flat pinnacle tooth are the maximum green layout for slicing and raking reduce cloth.

Change top Bevel (ATB)

Which means that the blade enamel exchange among left and proper bevels. This configuration produces a smoother cut when cross-reducing natural wood and veneer plywood. Alternating bevel teeth create a knife-like facet on each sides of the blade and are purifier than flat-pinnacle tooth.

Aggregate enamel (Comb)

Aggregate blades are designed for go slicing and tearing. The enamel are arranged in organizations of 5 - 4 ATB enamel and one feet - with a big socket among every group.

Triple Chip Grinding

The TCG configuration excels at reducing difficult materials such as laminate, MDF and plastic. Teeth change between flat "rake" enamel and taller "trapeze" tooth. The TCG configuration is likewise used for non-ferrous metal slicing blades.

High Alternating top Bevel

Configured for extremely-nice cross-cuts and cut surfaces with melamine surfaces that are vulnerable to chipping. The high bevel attitude will increase the knife-like motion of the threshold of the blade.

Hook attitude

Hook perspective has a giant impact on blade operation. A blade with a excessive advantageous rake attitude (eg, 20°) will produce very aggressive cuts and fast feed fees. A low or bad rake perspective slows the feed price and additionally inhibits the blade's tendency to "climb" the fabric being cut. Blades used to rip wooden on desk saws generally have a excessive rake angle, and commonly you want competitive, speedy cuts. Radial arm saws and sliding compound miter saws, then again, require blades with very low or poor rake angles to suppress immoderate feed charges, bonding, and the tendency of the blade to "climb" the material.

Reduce width

The width of the "kerf" -- the groove the blade makes in the material -- is any other essential consideration. Many blade types have each complete and skinny kerfs. Full kerf blades generally reduce 1/eight" slots for saws powered by means of a three hp (or large) motor.

In-kerf Blade - Blades with kerf thickness much less than 1/8" - evolved for use with portable and contractor model table saws with motor electricity less than three hp. Due to the fact a skinny kerf blade need to cast off much less fabric than a full kerf blade, it calls for less energy to function and allow a low power noticed to cut material on the proper feed price without bogging down the cut. (Bogging can motive excessive friction; consequently, the blade heats up and might warp or burn the reduce floor.)

A capacity tradeoff of thinner cuts is that the blade plate is thinner and consequently might also vibrate extra than a thicker, extra rigid plate. However, technological improvements in blade layout have produced skinny kerf blades that rival the quality commercial high-quality full kerf saw blades. Vibration discount structures, consisting of the ones used with Floyd's quality kerf blades, make amends for the slight loss of balance and make thin kerf blades the great preference for low-energy saws.

Noticed blade teeth quality

The teeth on most first rate saw blades are thick carbide hints which have been fused (or brazed) to the metallic blade plate. How long the blade remains sharp, how smooth the reduce is, and the way regularly it needs to be re-sharpened all depend on the satisfactory of the slicing tip. On a number of the excellent inserts, carbide is specially formulated for the blade's utility, and a tri-metallic brazing manner is used to connect the carbide device to the blade plate. The process sandwiches a layer of copper alloy among layers of silver alloy, which affords extra flexibility and impact resistance. At a minimum, search for inserts with C3 grade micrograined carbide teeth thick sufficient to permit more than one regrinds.

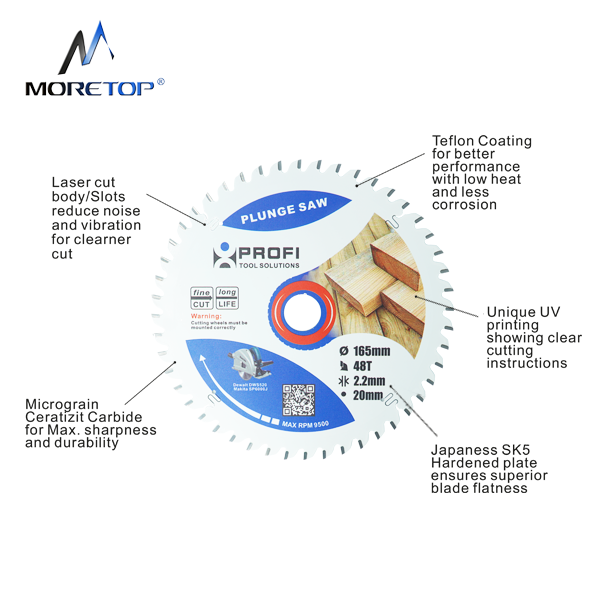

Unique UV printing to show clear cutting instruction.

Unique UV printing to show clear cutting instruction.