What to Consider When Choosing the Best Jigsaw Blade

- Share

- Issue Time

- Apr 23,2022

Summary

Combination puzzle blade sets offer versatility and good value, and it's no surprise that they're very popular. However, the sheer range of options can be confusing, as well as the number of specialty blades that provide more efficient saws for specific materials. Read on to discover the key features shoppers need to consider when choosing the best puzzle blade for a specific task.

Combined jigsaw blade sets offer versatility and good value, and it's no surprise that they are very popular. However, the sheer number of options can be confusing, as can the number of specialist blades that offer more efficient sawing for specific materials. Read on to discover the key features shoppers need to consider when choosing the best puzzle blade for a particular task.

material

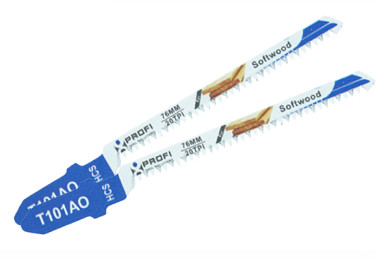

Four materials or combinations of materials are commonly used to make jigsaw blades: high carbon steel (HCS), high speed steel (HSS), bimetal (BiM), and tungsten carbide (often referred to as carbide for short).

High carbon steel is the best low-cost material for wood cutting blades. Cutting metal is not hard enough, although manufacturers sometimes add cobalt for this purpose.

High speed steel is much harder than high carbon steel and is commonly used for metal cutting blades. But, it can be crunchy. Some manufacturers produce high quality HSS blades, but bimetallic blades are more common.

Bimetal is a combination of high carbon steel and high speed steel with the best properties of both materials. These blades resist overheating, stay sharp much longer than HCS, and cut most materials very efficiently.

Tungsten carbide is an extremely hard compound. When making jigsaw blades, it is often used to strengthen teeth or as grit bonded to toothless blanks. The latter use -- without teeth -- does not work with wood or metal, but can cut tiles and other ceramics, glass and fiberglass.

Blade length and thickness

Whenever possible, the blade should be at least half an inch longer than the thickness of the material being cut. If the blade is too short, it has the potential to jump out of the cut as the jigsaw moves up and down, often breaking the blade. Please note that there may be a difference between the actual blade length and the effective or working length, depending on different assembly methods and tooth profile. Manufacturers usually indicate this by providing maximum cutting depth.

It is also important that the blade is not too long. The longer the blade, the greater the chance of bending, making it difficult to follow the cutting line. However, it's not expensive to have a variety of blades, which means you usually have the right length on hand.

Although there is little change in blade thickness, thinner blades can cut tighter curves than thicker versions if chosen. Of course, thinner blades are also more likely to break and wear out faster.

The final factor is the puzzle itself. It is important to understand specifications because not all tools will accept all available blade lengths.

The handle type

Most of the best puzzle blades have t-handles. In most cases, jigsaw pieces that accept t-handled blades have a tool change-free mechanism, so this is a quick and easy process. This is the most common blade type in use today, and almost all new puzzles use them.

Older models may use u-shaped handles, and blades of this type are still readily available. U-shank blades have a screw or hex socket bolt to hold them in place, so replacement takes more time. Remember to check which type you need, as T - and U-handle blades are not interchangeable.

It may not be obvious which type of handle is required for older puzzles. In this case, try universal handles, although "universal" is a bit of a misnomer as they don't fit all machines. There are also limited varieties.

Older puzzles may also have proprietary blade fittings. Some Maeda puzzles, for example, have blades dedicated to the brand. Finding these blades can be challenging, so if the tool is older, buying new puzzles may be a better long-term solution.

Tooth profile

The number of teeth per inch (TPI) has a significant impact on blade performance. In general, fewer teeth means faster and rougher cuts, and more teeth means slower and smoother cuts. The actual blade TPI can range from 6 to 32. But there are other factors to consider.

A high TPI means there is little space between the teeth for waste removal. For example, using 18 TPI blades in wood can lead to blade clogging. In contrast, 6 TPI is too low to cut metal because the teeth will only bounce off the surface. Although there are always exceptions, wood jigsaw blades are usually between 6 and 12 TPI. The typical jigsaw blade is eight to 14 TPI for plastic and laminate, and 14 to 24 TPI for metal.

The shape and pattern of the teeth also changed. For example, reverse cut jigsaw blades down stroke instead of up stroke. These reduce tearing of wood and chipping of laminate, making them popular for sawing kitchen countertops and floors. Other blades are called "jumpers" in which the tooth area is shorter or completely missing. These gaps allow the removal of difficult wastes, such as those produced when cutting certain plastics.

Some blades have no teeth at all -- not just the carbide versions mentioned above, but those designed to cut the knife-like wavy edges of polystyrene, leather and other fabrics. For people who regularly cut a material, it's worth looking for a blade designed specifically for that material. They will cut faster and more accurately than general-purpose alternatives.

Unique UV printing to show clear cutting instruction.

Unique UV printing to show clear cutting instruction.