Circular and miter saw blades buying guide

- Share

- Issue Time

- Apr 15,2022

Summary

Buying the right blade for your circular and/or miter saw is critical for safety reasons, and to ensure you choose the right blade for the type of cut and finish you're after. In this Toolstop buying guide, we'll show you how to choose the right circular saw blade for your power tool and the job you're doing. Click here to see all the different blades we offer for your miter and circular saws.

what circular saw blade to use

Buying the right blade for your circular and/or miter saw is critical for safety reasons, and to ensure you choose the right blade for the type of cut and finish you're after. In this Toolstop buying guide, we'll show you how to choose the right circular saw blade for your power tool and the job you're doing. Click here to see all the different blades we offer for your miter and circular saws.

Everything you need to know about circular saw blades

Buying Circular and Miter Blades - Size Matters

First, check the hole size on the machine. This may be more important if you are renting a saw. Make sure the blade you're installing is suitable for the saw you're using, starting with the drill hole. You can find this information in the user manual.

A saw with a 30mm hole diameter requires a 30mm hole diameter blade. It's that simple.

The diameter of the blade is also important. A blade diameter that is too large may affect any guards installed on the saw. Again, this is a security issue. The saw's owner's manual will outline the maximum and minimum blade diameters you can safely use on the machine. The thickness of the blade will determine the width of the cut. Finer, more precise cutting applications will require thinner diameter blades.

All measurements will be etched into the blade itself and clearly marked on the packaging.

It's worth pointing out that a good blade cuts a notch from the disc itself. This allows the disk to expand as it heats up as it is cut, thus preventing warping. A warped blade can mess up your cut and be a potential hazard to your health!

Buying and installing the correct size saw blade is critical to your safety.

Saw Blade Teeth Explained

If your application is cutting hardwoods and you want a clean cut surface, then try a fine-toothed blade. Because of their high tooth count, they cut through materials quickly and easily and leave nice, crisp edges when cutting. The same applies if you cut aluminum or plexiglass. The shape of the teeth, the number of teeth and the quality of the tungsten carbide means you'll be cutting fast, but you'll be left with lovely, clean straight edges.

However, it's worth pointing out that blades with more teeth generally require your saw to work slower and harder. But it is the teeth on the blade that make the cut, which will determine the quality of the final cut.

What type of finish can I achieve with a circular saw blade?

Buy Circular and Miter Blades - Cutting Matters

The blade you buy and attach to the saw will produce a cut specific to the manufacturer's design. The types of cuts that can be achieved are usually:

very rough cut

Fast cutting and cross-cutting of softwood, hardwood, raw particleboard and formwork

rough cut

Tearing and cross-cutting of softwood, hardwood, raw particleboard, formwork, board and plywood

fine cut

Cross-cutting of cork, plywood, wood core plywood, single-sided laminated particleboard and parquet

cut very thin

Crosscuts for cork, hardwood, plywood, wood core plywood, parquet, fibre materials and MDF

what saw blade to use

What circular saw blade do I need?

The cuts performed by the blade actually come entirely from the teeth, not the disk itself. Therefore, the type of teeth on the blade you choose will have the biggest impact on the material. Selecting the correct tooth profile is critical in terms of cut quality and personal safety.

First, the more teeth on the blade means a finer and more precise cut.

The high number of teeth, combined with the thin blade, means it is ideal for fine, precise cutting of parquet and laminate. And because the teeth (or blades) are made of tungsten carbide, they are very wear-resistant and can be reground, allowing you to get the most out of their life.

Another factor to consider is the shape of the blade teeth. The shape of the teeth that cut into the tungsten blade will affect the quality of the cut you will get. Some examples of profiled teeth are alternating top bevels. This is where a tooth is angled in one direction and the one behind it is angled in the other. Teeth like these are great for quick cuts, possibly through rough wood, especially along or through the grain.

The best blade for a miter saw

Buying Circular and Miter Blades - Height Matters

Perhaps the most obvious, but also the most overlooked, is making sure you buy and use the right circular saw blade. When buying and using a circular saw blade, not only make sure that you are buying the correct size, shape and number of teeth, but that you are using the correct height in the machine.

Remember, it's the teeth that actually make the cut.

The blade or disc portion is only used to - literally - support the teeth. The teeth are sharpened, ground and designed for cutting. So setting your machine to the correct cutting height (or depth) will determine whether you're getting the most out of the blade, rather than putting too much stress on your machine. When cutting, the teeth of the blade can only protrude from the cut, no more than a few millimeters or so. This means the teeth will be in contact with your cutting material at the right angle, your machine will be able to run at optimal cutting speed and you will experience less drag and vibration.

We hope this guide has helped you understand the different types of saw blades, the number of teeth, and which blade should be used for each application. We offer a wide range of circular saw blades at Toolstop which you can purchase below. The range includes some miter saw blades for wood and all others for circular saws.

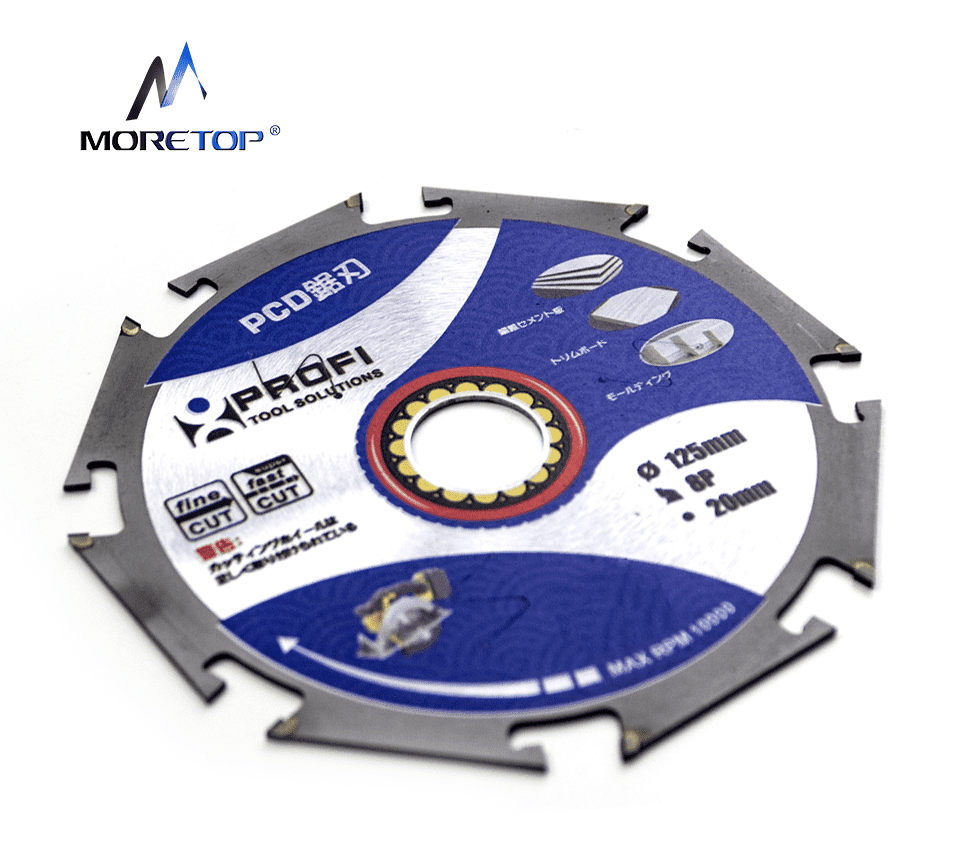

PROFI TCT Circular Saw Blades for metal cutting, offer high performance and long life.

It’s produced by vacuum brazing technology for firmly attached diamond particles, fast cutting/drilling and long service life.

Moretop plunge saw blades are specially designed for different plunge saws like Festool, Dewalt, Bosch, Mafell.

Unique UV printing to show clear cutting instruction.